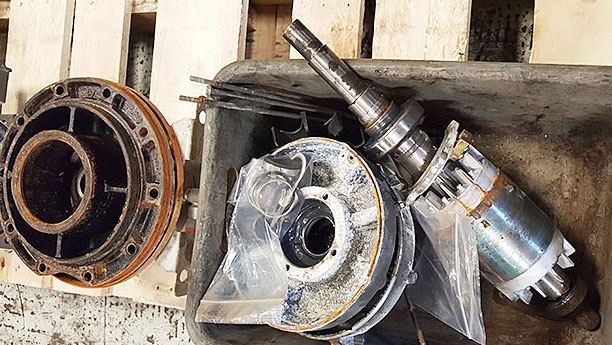

Is this how your equipment looks?

Every pump will fail from time to time. How do you know where to start troubleshooting the failure?

We at Detroit Pump are sharing our quick reference charts for troubleshooting Hydraulic and Mechanical pump failure. Here you’ll see some of the symptoms of pump failures and what the possible causes could be. Use these handy reference guides as a starting point to determine possible problems before tearing into the pump. Save man hours and costs by not taking pumps apart until the possible causes are identified.

Symptoms & Causes of Hydraulic Pump Failures

| Symptoms & Causes of Hydraulic Pump Failures | Pump does not deliver liquid | Pump does not deliver sufficient capacity | Pump does not deliver sufficient pressure | Pump delivers flow intermittently |

|---|---|---|---|---|

| Pump not primed or prime lost | x | x | x | x |

| Suction and/or discharge valves closed or clogged | x | x | ||

| Suction piping incorrect | x | x | x | |

| Insufficient NPSH available | x | x | x | |

| Excessive air entrapped in liquid | x | x | x | x |

| Speed (rpm) too low | x | x | x | |

| Incorrect rotation | x | |||

| Broken impeller or bent vanes | x | x | ||

| Incorrect impeller or impeller diameter | x | x | ||

| System head too high | x | |||

| Instruments give erroneous readings | x | x | ||

| Air leak in suction | x | |||

| Impeller clogged | x | |||

| Pump assembled incorrectly | x |

![]()

Hydraulic_Pump_Failures_Symptoms-Causes.pdf

Symptoms & Causes of Mechanical Pump Failures

| Symptoms & Causes of Mechanical Pump Failures | Bearings Run hot and/or fail on regular basis | High rate of mechanical seal failure | Packing has short life | Pump vibrates at higher than normal levels | Pump is drawing too much power | Wear of internal wetted parts is accelerated | |

|---|---|---|---|---|---|---|---|

| Pump not primed or prime lost | |||||||

| Suction and/or discharge valves closed or clogged | x | ||||||

| Suction piping incorrect | |||||||

| Insufficient NPSH available | x | x | x | ||||

| Excessive air entrapped in liquid | |||||||

| Speed (rpm) too low | |||||||

| Incorrect rotation | x | ||||||

| Broken impeller or bent vanes | x | x | |||||

| Incorrect impeller or impeller diameter | |||||||

| System head too high | |||||||

| Instruments give erroneous readings | |||||||

| Air leak in suction | |||||||

| Excessive shaft misalignment | x | x | x | ||||

| Inadequate lubrication | x | ||||||

| Lubricant contamination | x | ||||||

| Inadequate lubricant cooling | x | ||||||

| Axial thrust or radial loads higher than bearing rating | x | ||||||

| Improper coupling lubrication | x | x | |||||

| Suction pressure too high | x | x | |||||

| Bearing incorrectly installed | x | x | |||||

| Impeller out of balance | x | x | |||||

| Overheating of seal faces | x | ||||||

| Excessive shaft deflection | x | x | |||||

| Lack of seal flush at seal faces | x | ||||||

| Incorrect seal installation | x | ||||||

| Pumps is run dry | x | ||||||

| Pump run off design point | x | x | x | x | x | ||

| Shaft/shaft sleeve worn | x | x | |||||

| Packing gland not properly adjusted | x | ||||||

| Packing not properly installed | x | ||||||

| Impeller clogged | x | ||||||

| Coupling out of balance | x | x | x | ||||

| Baseplate not installed properly | x | x | x | ||||

| Pump operating speed too close to system’s natural frequency | x | ||||||

| Bearing failing | x | x | x | ||||

| Piping not properly anchored | x | x | x | ||||

| Pump and/or driver not secured to baseplate | x | x | x | ||||

| Specific gravity higher than specified | x | x | x | ||||

| Viscosity higher than specified | x | x | x | ||||

| Internal clearances too tight | x | x | |||||

| Chemicals in liquid other than specified | x | ||||||

| Pump assembled incorrectly | x | x | x | x | x | ||

| Higher solids concentration than specified | x | ||||||

![]()

Mechanical_Pump_Failures_Symptoms-Causes.pdf

In a future blog, we will break down some causes and how to start to dive deeper into finding the problem. If you have a pump in trouble, we are here to assist you.